OBJECTIVES

The ARHYOSA™ project aims to create the first Italian platform for the management and monitoring of machinery involved in green hydrogen production, adopting an “as a service” approach. The platform brings together Italian excellence in Green Tech, AIoT, and industrial certification to support the energy transition and decarbonization.

Through the integration of advanced technologies such as EDGEAI, GENAI, and XAI, the ARHYOSA™ solution will offer high value-added services—not only technical, but also insurance, financial, and predictive. Based on EaaS (Equipment as a Service) patents and technologies, the platform will be tested on an innovative electrolysis plant designed by AGT, which uses renewable energy to produce carbon-free hydrogen following the Power-to-Hydrogen (P2H) model.

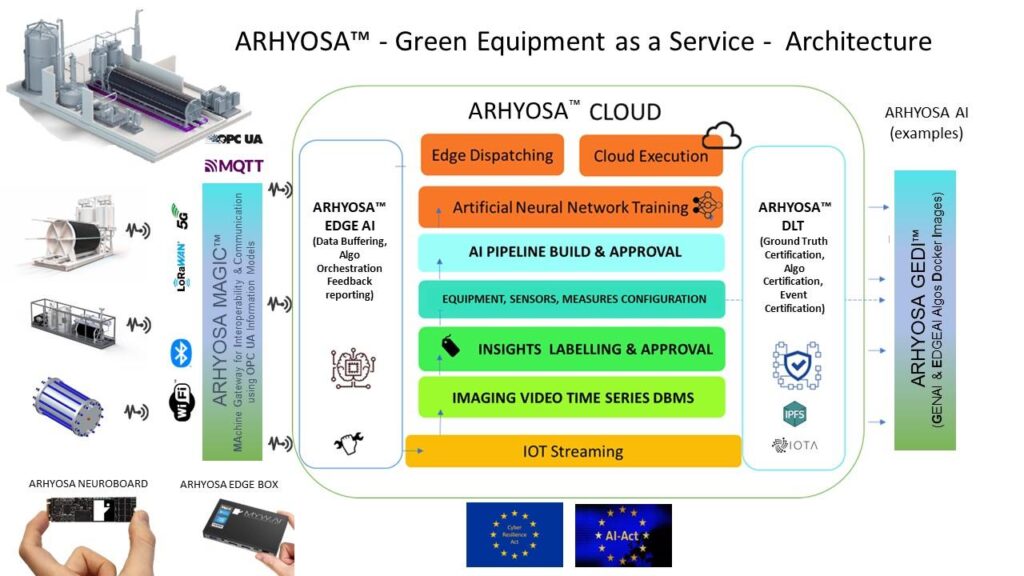

The platform will include the following key components, as illustrated in the figure:

- ARHYOSA CLOUD™: for continuous monitoring of time-stamped data from Green Tech machinery.

- ARHYOSA EDGE™: for certified processing of AI algorithms in an edge computing environment.

- ARHYOSA DLT™: for certification of data, AI algorithms, and energy parameters using distributed ledger technologies (DLT).

In addition to integrating pre-existing modules, the development and integration of two brand-new modules are also planned:

- ARHYOSA MAGIC™: for semantic interfacing of machinery, based on semantic digital twins and OPC UA™ standards.

- ARHYOSA GEDI™: for the secure management and distribution of AI algorithms in Docker™ format and datasets in compliance with European regulations.

ARHYOSA™ will contribute to the decarbonization of key sectors such as transport, industry, and energy, enabling the integration of renewable energy production and use through the Power-to-X (P2X) model.

EXPECTED RESULTS

The implementation of ARHYOSA™ will deliver tangible benefits in the industrial sector:

- Improved workplace safety, with a significant reduction in operational risks.

- Optimization of production processes, enabled by more precise quality control.

- Reduced machine downtime, thanks to real-time monitoring and artificial intelligence algorithms.

- Advanced training, through a continuous learning system for technicians and operators.

The platform will be tested in a pilot production area of Ansaldo Green Tech (a project partner), where the Test Bench HMI will collect operational data from the electrolyzers, providing rapid analysis and identifying anomalies or early signs of potential issues—thus ensuring the development of more reliable and sustainable products.

ARHYOSA™ will also support new opportunities for the industrial supply chain, such as certification services for innovative processes developed by the coordinator MYWAI, in collaboration with other project partners (KHE, IIS, and TIC), contributing to the transition toward a low-carbon, high-energy-efficiency economy.

Test Bench HMI

The Test Bench HMI is a testing station that uses a Human-Machine Interface (HMI) to collect and display real-time data from AEM electrolyzers. It allows operators to monitor key parameters such as temperature, pressure, and energy consumption, enabling quick intervention in case of anomalies.

Thanks to this interface, prototype performance can be optimized, improving reliability and reducing downtime.