Seneca™ Project Implementation

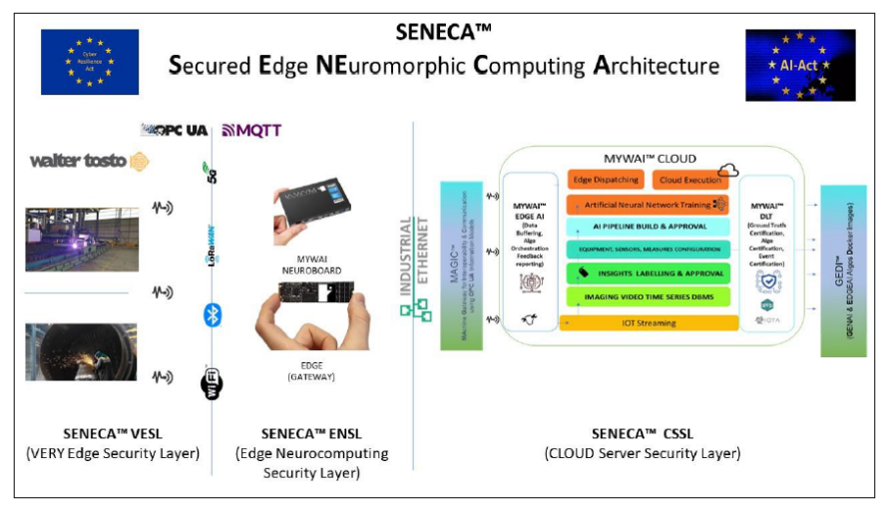

The three security levels defined at the architectural level have been implemented within the platform and configured for data acquisition at pilot sites.

The SENECA system’s security architecture consists of the following levels:

- Level 1 (SENECA™ VESL – Very Edge Security Layer):

Design of a secure communication channel between the VERY EDGE and EDGE layers, enabling data transfer from the OT (Operational Technologies) domain to the IT (Information Technologies) domain over the web. - Level 2 (SENECA™ ENSL™ – Edge Neurocomputing Security Level):

Design of the second-level security layer to safeguard the edge computing chain for AI algorithm processing. - Level 3 (SENECA™ CSSL – Cloud Server Security Level):

Design of additional MLOps services to secure the SENECA™ architecture through:- Creation of a GDS (Global Discovery Service) Server for discovering welding machines equipped with OPC UA servers or clients, and registering them with the central cloud.

- Development of a PKI (Private Key Infrastructure) for issuing authorization and authentication certificates for algorithms and devices.

- Setup of a distributed workflow environment to enable shared approval of algorithms and datasets in the cloud.

- Design of an architecture for dataset and algorithm certification on a DLT (Distributed Ledger Technology) framework.

- Very Edge Security Layer (SENECA™ VESL): Ensures the security of sensors and peripheral devices through vulnerability assessment and the creation of secure communication channels between VERY EDGE and EDGE devices, taking into account the technological diversity and security limitations of existing industrial sensors.

- Edge Neurocomputing Security Level (SENECA™ ENSL): Implements a secure trust chain for neurocomputing algorithms, which can be integrated into standard industrial computers for effective testing on dedicated hardware, optionally using neuromorphic chips.

- Cloud Server Security Level (SENECA™ CSSL): Provides MLOps services for the certification of XAI (Explainable AI) algorithms, with a distributed workflow across cloud and hybrid architectures based on DLT (Distributed Ledger Technology) and distributed file systems to ensure transparency and reliability.

All components will be integrated and tested directly on production plants using welding defect recognition algorithms within the industrial demonstrator for weld defect classification, installed at the Italian Institute of Welding in accordance with specifications provided by WALTER TOSTO™.

EXPECTED RESULTS

By 2025, 75% of enterprise data will be generated at the edge, with artificial intelligence covering over 65% of use cases by 2027—creating a major opportunity for AI/ML providers. The EDGE AI market, valued at $14,787.5 million in 2022, is projected to grow at an annual rate of 21% from 2023 to 2030, driven primarily by the hardware segment (53.6% in 2022), especially IoT devices equipped with AI processors for diagnostics, surveillance, and quality control.

Security in deploying AI solutions on the edge has therefore become a critical necessity.

Technologies such as blockchain (DLT) integrated with cybersecurity and edge computing, as seen in SENECA™4.0, represent a solution for AI that is more secure, transparent, and explainable.

The project strengthens the leadership of Ligurian SMEs MYWAI™ and KNOWHEDGE™, which have developed advanced EDGE AI technologies, integrating them with a “secure by design” infrastructure for delivering AI algorithms at the edge. This infrastructure is supported by START 4.0 and UNIGE, and validated by the Italian Institute of Welding according to specifications provided by WALTER TOSTO™ SPA, a global leader in Industry 4.0.